3D Printing News Briefs, August 17, 2024: 3D Printed Catalysts, Organs, Therapeutics, & More – 3DPrint.com

In 3D Printing Information Briefs, America Makes introduced the winners of the PADAM venture, New Zealand analysis companions are 3D printing rocket gas catalysts, and researchers with UVA developed voxel constructing blocks for 3D bioprinted organs. Carbon and SprintRay partnered for a cloth validation, and Triastek is partnering with BioNTech to superior 3D printed oral RNA therapeutics. UpNano and Glassomer co-developed a novel technique for 3D printing macro-sized fused silica glass. Lastly, a product designer turned FDM purge blocks into 3D printed truck cargo for a museum exhibit.

Winners of PADAM Undertaking Introduced by America Makes & NCDMM

America Makes and the Nationwide Middle for Protection Manufacturing and Machining (NCDMM) have introduced the winners of the Powder Alloy Improvement for Additive Manufacturing (PADAM) venture, which is being funded for $6 million by the Air Pressure Analysis Laboratory (AFRL). The venture expenses the award winners to arrange data-driven strategies for making use of the most effective attributes of novel steel AM supplies. For Subject 1, “Excessive-Temperature Refractory Alloys,” Castheon will lead the “Maturing AM Expertise for C-103 in Hypersonics and House (MATCHAS)” venture, with workforce members 3Degrees; Amaero; AP&C Superior Powders & Coatings, Inc.; ATI Specialty Alloys and Parts; Benchmark House Programs; Blue Origin; Firefly Aerospace. FormAlloy; Lockheed Martin; NASA John H. Glenn Analysis Middle; NSL Analytical; Rolls-Royce Company; and Spirit Aerosystems. For Subject 2, “Excessive-Temperature Nickel-Primarily based Superalloys,” Boeing will lead the “Accelerated Maturation of Superior Excessive-Efficiency Ni-Primarily based Superalloy ATI-1700™ for Additively Manufactured Excessive Setting Parts” venture, with workforce members ATI Specialty Metals, Quintus Applied sciences, and RPM Improvements.

“We’re embarking on an extremely thrilling period throughout the AM sector. Exploring the probabilities of AM materials functions is a step in the correct course with appreciable implications for the way forward for aerospace and protection. The Institute is extremely lucky to have the help of the Underneath Secretary of Protection and AFRL and the engagement of the brightest minds within the nation who shall be collaborating to revolutionize this know-how,” mentioned Brandon Ribic, Expertise Director at America Makes.

Kiwi Researchers 3D Printing Greener Catalysts for Rocket Gas

Platinum catalysts with ceramic gyroid and honeycomb buildings, exhibiting the distinction between conventional and novel 3D printed catalysts.

A easy catalytic response—turning hydrazine into sizzling increasing gasses—has lengthy been used to maneuver issues in area. Sadly, hydrazine may be very poisonous and probably a carcinogen, so excessive ranges of non-public protecting gear (PPE) are wanted throughout refueling. Propellants with decrease toxicity are wanted, and one “inexperienced” various is concentrated hydrogen peroxide, or high-test peroxide (HTP). Whereas it has a decrease thrust output, the gas has the next density and is comparatively benign, and more cost effective in volume-constrained techniques. There are potential functions in rocket-powered plane and satellites, however HTP thruster know-how hasn’t modified a lot for the reason that Sixties, so there are points. A New Zealand analysis partnership between Daybreak Aerospace, the College of Canterbury, and Callaghan Innovation is seeking to innovate HTP thrusters, to allow them to function a substitute for harmful hydrazine.

Additive manufacturing permits way more design freedom, so it’s potential to create catalyst buildings that improve mass switch, whereas on the similar time decreasing the strain drop; each are widespread points with conventional manufacturing. The workforce centered on a category of buildings known as triply periodic minimal surfaces (TPMS), and decided that the gyroid unit cell geometry could be ultimate for HTP thrusters. They used digital mild processing (DLP) know-how to print novel catalyst helps out of ceramic, which has glorious thermal and chemical stability, and the catalyst lively section was platinum. To evaluate whether or not the 3D printed catalyst helps actually provided higher mass transport, greater thrust output, and decrease strain drop, the workforce put in them in a small take a look at platform equal to a ten N HTP thruster and measured their efficiency. They had been finally profitable, reaching thermal efficiencies of >90% with a decrease strain drop, and the 3D printed helps had been absolutely intact as soon as faraway from the platform.

UVA Researchers Create Voxel Constructing Blocks for 3D Printed Organs

Harking back to a raspberry, this voxelated hole sphere made from a single layer of droplets was generated utilizing digital meeting of spherical particles, or DASP, a 3D bioprinting course of developed in assistant professor of supplies science and engineering Liheng Cai’s lab. (Mushy Biomatter Lab, UVA Engineering). Credit score: College of Virginia College of Engineering and Utilized Science/Liheng Cai

Researchers on the College of Virginia College of Engineering and Utilized Science printed a paper sharing the outcomes of their distinctive bioprinting technique: digital meeting of spherical particles, or DASP. It permits them to make biomaterials with managed mechanical properties that match these of human tissues. DASP deposits water-based polymer hydrogels, engineered to imitate human tissue and containing precise human cells, in a water-based supporting matrix to construct 3D buildings that provide a great atmosphere for cell progress—similar to how voxels assemble 3D objects. This course of might be the template for the primary constructing blocks for on-demand 3D printing of human-compatible organs. The workforce’s “double community” hydrogels are extra biocompatible, much less poisonous, and mechanically robust, however very tunable to get the correct tissue traits. They achieved this by designing a fast-moving, multichannel nozzle for on-demand mixing of the hydrogel parts, and enormous droplets are instantly suspended within the matrix.

“Our new hydrogel particles signify the primary practical voxel we’ve got ever made. With exact management over mechanical properties, this voxel might function one of many fundamental constructing blocks for our future printing constructs,” mentioned PhD scholar Jinchang Zhu, who labored with Liheng Cai, an assistant professor of supplies science and engineering and chemical engineering, on this analysis.

“For instance, with this stage of management, we might print organoids, that are 3D cell-based fashions that perform as human tissue, to check illness development within the seek for cures.”

Carbon & SprintRay Validate OnX Robust 2 Resin for M-Collection 3D Printers

Carbon and SprintRay partnered to validate the usage of SprintRay’s OnX Robust 2 dental resin with Carbon’s M-series 3D printers for making mounted hybrid dentures. Clinicians across the U.S. have already adopted OnX Robust 2, which is thought for its glorious energy and aesthetic qualities, however that is the primary time SprintRay has collaborated with one other 3D printing firm. This resin is FDA-cleared for 3D printing mounted hybrid dentures, and NanoFusion Expertise helps particle distribution within the materials for improved visible high quality and sturdiness. It’s additionally out there in 5 completely different shades to satisfy affected person wants, and the power to print this resin on M-series printers will enable dental labs to develop their capabilities with enhanced service choices.

“SprintRay’s collaboration with Carbon underscores our dedication to delivering revolutionary options that improve the capabilities of dental labs,” mentioned Amir Mansouri, PhD, CEO and Co-Founding father of SprintRay. “The validation of OnX Robust 2 on the Carbon platform marks a big milestone in dental 3D printing, enabling labs to realize distinctive sturdiness and aesthetic high quality of their restorations. This partnership not solely expands our market attain but in addition reinforces our dedication to advancing dental care.”

Triastek & BioNTech Companion to Advance 3D Printed RNA Therapeutics

International 3D printing prescribed drugs chief Triastek, Inc. has entered right into a analysis collaboration and platform know-how license settlement with immunotherapy firm BioNTech SE, which creates novel therapies for most cancers and different critical ailments. The 2 will develop 3D printed RNA therapeutics to deal with unmet wants for an oral formulation that’s straightforward to manage. Per the phrases of the settlement, Triastek will get an upfront fee of $10 million, and be eligible to obtain improvement, regulatory and industrial milestone funds that might whole over $1.2 billion, along with tiered royalties on potential future product gross sales. Triastek’s Soften Extrusion Deposition (MED) shall be used to create oral pill buildings with distinctive geometries, together with multi-layer and multi-compartment capsule designs, as a way to optimize supply of novel RNA therapeutics throughout the gastrointestinal mucosa. This may scale back degradation within the gastrointestinal tract, and ship therapeutics to the realm the place absorption will doubtlessly be the best.

“We’re immensely honored to announce our collaboration with BioNTech, a frontrunner in revolutionizing affected person care with transformative medicines. We imagine this collaboration stands as a promising milestone in advancing oral RNA therapeutics utilizing 3D printing know-how and goals to set new benchmarks within the improvement of huge molecule oral medication,” mentioned Dr. Senping Cheng, Founder, and CEO of Triastek. “We’re dedicated to working diligently collectively to make breakthroughs in oral supply of RNA therapeutics.”

Novel 3D Printing Course of for Macro-sized Fused Silica Elements

Eiffel Tower, straight printed from UpQuartz, showcasing the obtainable complexity in addition to exceptional measurement that may be achieved with UpQuartz. The tower is 10 mm excessive and has intricate options that attain into the tens of micrometers vary. © UpNano

Austrian firm UpNano and Glassomer, primarily based in Germany, co-developed a novel 3D printing course of for fused quartz objects, with high-resolution options, within the mm and cm vary. It’s powerful to fabricate complicated, miniature 3D objects in glass, particularly when it’s fused silica (SiO₂) glass, which has a really excessive melting level and is coveted for its biocompatibility, glorious warmth resistance, and excessive chemical inertness. Present strategies may end up in merchandise with tough surfaces, however this course of, modified for Glassomer’s two-photon polymerization (2PP) utilizing UpNano’s high-resolution printing system, can 3D print macro-sized fused silica components which are clean and have options within the μm vary. On the middle of the method is UpQuartz, a brand new nanocomposite containing a specifically designed polymer matrix that allows it to be printed with 2PP.

“It’s a three-step course of. Step one is to design and print the specified construction utilizing all the benefits 2PP 3D-printing provides. The second step is to take away natural binder materials adopted by a excessive temperature sintering course of, the third step,” defined Markus Lunzer, workforce lead of Supplies & Utility at UpNano.

“This revolutionary manufacturing course of we developed is ideally suited to bigger 3D-printed glass components that require high-resolution and high-precision, within the fields of engineering, and chemical, medical or analysis functions.”

FDM Purge Blocks Turn into Creative Cargo for Multicolored Vans

Picture: Dan Perez, courtesy of Dov Ganchrow

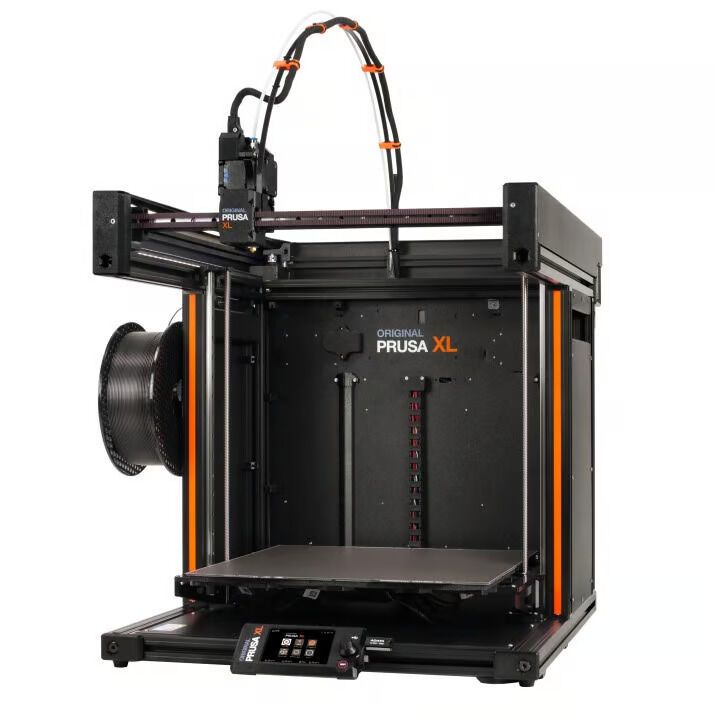

Artist and product designer Dov Ganchrow, a professor on the Bezalel Academy of Arts and Design in Jerusalem, was commissioned by the Holon Design Museum to create a chunk for its “Shade” exhibit, which lasts by means of December 21, 2024. The result’s the Purgey Vans venture, curated by Liora Rosin and Yuval Saar, wherein Ganchrow explores the intersection of know-how and shade by means of FDM 3D printing. One well-known function of FDM is the creation of purge blocks, or purge towers—as a printer switches colours, it cleans the extruder by depositing further plastic filament from the primary shade subsequent to the print in a dice. For the venture, Ganchrow 3D printed multicolored vehicles on a single-extruder Prusa FDM printer out of filaments composed of varied shade segments. However as a substitute of throwing away the purge blocks, Ganchrow turned them into a big aspect of the piece.

Ganchrow started by unraveling a digital object to see the filament’s sequential shade composition. Completely different coloured segments had been minimize and merged collectively by means of phase fusion to make bodily filament, which was then used to print the vehicles with out helps, inflicting the creation of angled kinds. The vehicles had been 3D printed standing on their heads, and as soon as completed, the purge block was moved onto the mattress of the truck as colourful cargo. One of many vehicles within the artwork piece truly carries a spool of fused filament, somewhat than a purge block. This represents the stage of the truck earlier than it’s printed subsequent to the block, and showcases the 3D printing course of and the materialization of the bodily object in a humorous means.

Subscribe to Our E-mail E-newsletter

Keep up-to-date on all the most recent information from the 3D printing business and obtain info and provides from third occasion distributors.