#3DExpress: Apple Watch Series 10 to Be Made With 3D Printing

Now that the weekend is lastly right here, we’re as soon as once more having a look again on the information of the week in our #3DExpress. Beginning it off, Apple analyst Ming-Chi Kuo has as soon as once more predicted that the corporate will probably be utilizing 3D printing for the Collection 10 Apple Watch. One other nice success for using additive manufacturing in client items. Subsequent, study all about Azul 3D’s subsequent 3D printer, Ocean, their greatest resolution but and Fizik’s optimized, 3D printed bike saddles. Wrap it up with the information about BigRep’s industrial 3D printer and the brand new chrome steel materials from XJet to be used with its NPJ options. Comfortable studying!

Apple Is As soon as Once more Utilizing 3D Printing for its Apple Watches

Apple analyst Ming-Chi Kuo is again! After predicting in July of final 12 months that Apple can be utilizing 3D printing within the Apple Watch Extremely, confirmed later in 2023, he has now predicted that the Collection 10 of the Apple Watch, starting within the 2nd half of 2024, will as soon as once more use components made utilizing 3D printing expertise. What has modified nonetheless is that the provider, BLT (who has additionally been making waves this 12 months) will probably be making the parts instantly. Additionally, after intensive testing that improved the manufacturing effectivity of 3D printing at Apple, mass manufacturing of 3D printed components is predicted. The watch can be anticipated to function a bigger display screen and a thinner design. Information to control!

Photograph Credit: Ming-Chi Kuo/Apple

Azul 3D Launches OCEAN™ 3D Printer

Azul 3D, a number one 3D printing startup recognized for its HARP™ expertise, has introduced the launch of its subsequent printer, named OCEAN™. Constructing upon its predecessor LAKE™, the 3D printer is predicted to take care of the 72um excessive decision and excessive pace of over 300 mm per hour (whereas nonetheless permitting for positive options), at a considerably bigger measurement. The construct space is, at 812 mm x 812 mm, comparatively massive for a resin resolution for what the corporate claims is the world’s largest and best area-wide 3D printing resolution. “Our technique is to empower the way forward for digital manufacturing,” confirmed John Hartner, CEO of Azul 3D. “The OCEAN platform is a new-to-industry functionality, with the chance to allow new high-volume merchandise and provide chains.”

Fizik Optimizes the Design of its Bicycle Seats

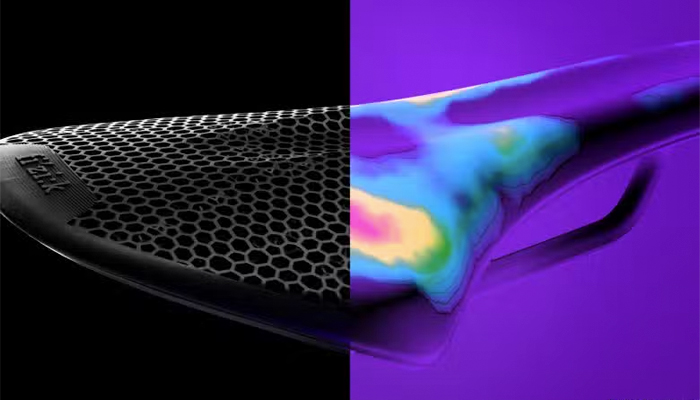

Based in 1996, Fizik is a sports activities gear firm born with the mission to supply the most effective options for the world’s most demanding cyclists. In collaboration with GebioMized, a German firm specializing in bicycle match and stress mapping knowledge, Fizik is optimizing its bicycle saddles. Collectively, the businesses designed a system to gather stress mapping knowledge from particular person cyclists to then design and 3D print a personalized saddle. This measurement methodology depends on the precise seated place on the bike to gather important knowledge on peak stress identifiers, stress factors and pelvic tilt. “We all know {that a} good, correct match depends upon many components: bike geometry, supposed use, saddle form, and place,” explains Giovanni Fogal, Model Supervisor at Fizik. “However most significantly each bicycle owner is exclusive: expertise, sensitivity, historical past of accidents, physique form, driving objectives. All of this will have an effect on the way in which we sit on the saddle. It’s clear {that a} conventional one-to-many saddle design can solely present an approximate resolution to very particular issues. With One-to-One right this moment we obtain what each saddle producer has all the time dreamed of: bringing to life personalized help out there to each bicycle owner.”

Photograph Credit: Fizik

BigRep Launches New Industrial FFF Printer

Simply yesterday, German printer producer BigRep GmbH introduced the launch of a brand new industrial 3D printer. The Bim VIIO 250 is a extremely automated FFF 3D printer that’s designed to course of technical and fiber-reinforced supplies to supply high-resolution components. A number of instruments be sure that the printing course of is as automated as potential and solely minimal handbook intervention is required. For instance, the printer is supplied with an Infinity Field for computerized filament dealing with and has a Relay Mode, a backup extruder performance that allows uninterrupted manufacturing. Additional highlights are the beneficiant construct chamber of 1000 x 500 x 500 mm and the open materials system. With the VIIO 250, BigRep is concentrating on environment friendly manufacturing for industrial functions, such because the automotive {industry}. Jens Krämer, Head of Prototyping at Magirus GmbH, has already been capable of check the printer as a producer of fireplace engines and enthuses: “It’s nice to see that ideas from the desktop printer sector are actually additionally discovering their means into the economic atmosphere. Having the ability to depend on the automated calibration of the print mattress, the filament throughput and the X and Y axes makes my day-to-day work a lot simpler and ensures dependable outcomes.” The BigRep VIIO 250 will probably be formally unveiled subsequent week at RAPID + TCT and in a digital launch occasion.

Photograph Credit: BigRep

XJet Provides New Stainless Metal Materials

Israeli industrial 3D printer producer XJet has simply added a brand new materials to its portfolio of options. The 17-4PH chrome steel is predicted to increase the economic functions now potential with the corporate’s patented NanoParticle Jetting expertise. The fabric has excessive tensile power and hardness. Andy Middleton, CBO of XJet, provides: “With the brand new resolution for 17-4PH, help supplies could be eliminated in down to 6 hours – a stark distinction to different AM processes. 17-4PH permits us to successfully collaborate with {industry} leaders to supply cutting-edge end-use components at distinctive designs, high quality and speeds that their respective industries is not going to have seen earlier than.” For these heading to the RAPID + TCT present subsequent week, you will discover some components 3D printed with this steel on the XJet sales space.

Photograph Credit: XJet

What do you consider the potential for 3D printed components within the Apple Watch Collection 10? Tell us in a remark beneath or on our LinkedIn, Fb, and Twitter pages! Don’t neglect to enroll in our free weekly publication right here for the most recent 3D printing information straight to your inbox! It’s also possible to discover all our movies on our YouTube channel.