New Multi-Material “Laser” 3D Printer Can Create Complex Devices With Just a Single Machine

College of Missouri researchers have developed a novel 3D printing methodology that permits the creation of advanced multi-material gadgets in a single course of, streamlining manufacturing and enhancing environmental sustainability. Credit score: Sam O’Keefe

An progressive 3D printing methodology simplifies the manufacturing of multi-material merchandise.

Researchers on the College of Missouri have developed a technique to create advanced gadgets with a number of supplies — together with plastics, metals, and semiconductors – all with a single machine.

The analysis, which was not too long ago revealed in Nature Communications, outlines a novel 3D printing and laser course of to fabricate multi-material, multi-layered sensors, circuit boards, and even textiles with digital elements.

It’s referred to as the Freeform Multi-material Meeting Course of, and it guarantees to revolutionize the fabrication of recent merchandise.

By printing sensors embedded inside a construction, the machine could make issues that may sense environmental circumstances, together with temperature and strain. For different researchers, that would imply having a natural-looking object comparable to a rock or seashell that would measure the motion of ocean water. For the general public, functions might embody wearable gadgets that monitor blood strain and different very important indicators.

Developments in 3D Printing Strategies

Particularly, different methods fall brief relating to how versatile the fabric will be and the way exactly smaller elements will be positioned inside bigger 3D buildings.

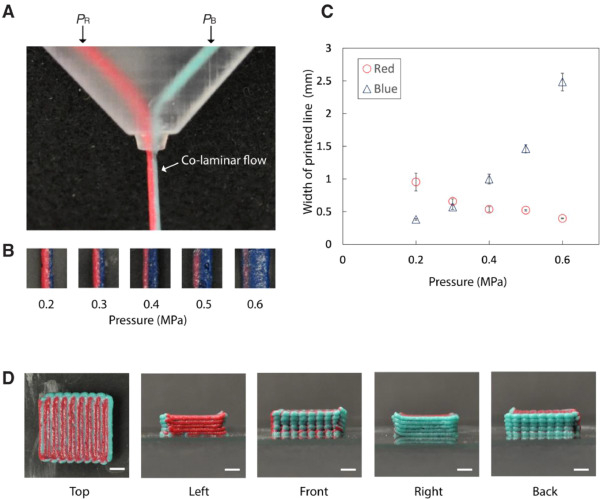

The Mizzou crew’s methodology makes use of particular methods to resolve these issues. Staff members constructed a machine that has three completely different nozzles: one provides ink-like materials, one other makes use of a laser to carve shapes and supplies, and the third provides extra purposeful supplies to reinforce the product’s capabilities. It begins by making a fundamental construction with common 3D printing filament, comparable to polycarbonate, a kind of clear thermoplastic. Then, it switches to laser to transform some elements right into a particular materials referred to as laser-induced graphene, placing it precisely the place it’s wanted. Lastly, extra supplies are added to reinforce the purposeful skills of the ultimate product.

This work is being funded by the Nationwide Science Basis (NSF) Superior Manufacturing program, and the NSF I-CorpsTM program is offering funds to discover commercialization.

“The I-Corps program helps us establish market pursuits and wishes,” Lin mentioned. “At present, we consider it could be of curiosity to different researchers, however we consider it is going to finally profit companies. It should shorten fabrication time for gadget prototyping by permitting firms to make prototypes in-house. This know-how, obtainable solely at Mizzou, exhibits nice promise for reworking the way in which merchandise are fabricated and manufactured.”

“That is the primary time this kind of course of has been used, and it’s unlocking new potentialities,” mentioned Bujingda Zheng, a doctoral scholar in mechanical engineering at Mizzou and the lead creator of the examine. “I’m excited concerning the design. I’ve all the time needed to do one thing that nobody has ever performed earlier than, and I’m getting to try this right here at Mizzou.”

One of many foremost advantages is that innovators can give attention to designing new merchandise with out worrying about learn how to prototype them.

“This opens the chance for solely new markets,” mentioned Jian “Javen” Lin, an affiliate professor of mechanical and aerospace engineering at Mizzou. “It should have broad impacts on wearable sensors, customizable robots, medical gadgets, and extra.”

Revolutionary methods

At present, manufacturing a multi-layered construction — comparable to a printed circuit board — generally is a cumbersome course of that includes a number of steps and supplies. These processes are pricey, time-consuming, and might generate waste that harms the atmosphere.

Not solely is the brand new method higher for the planet, it’s impressed by techniques present in nature.

“All the things in nature consists of structural and purposeful supplies,” Zheng mentioned. “For instance, electrical eels have bones and muscle mass that allow them to maneuver. Additionally they have specialised cells that may discharge as much as 500 volts to discourage predators. These organic observations have impressed researchers to develop new strategies for fabricating 3D buildings with multi-functional functions, however different rising strategies have limitations.”

Reference: “Programmed multimaterial meeting by synergized 3D printing and freeform laser induction” by Bujingda Zheng, Yunchao Xie, Shichen Xu, Andrew C. Meng, Shaoyun Wang, Yuchao Wu, Shuhong Yang, Caixia Wan, Guoliang Huang, James M. Tour and Jian Lin, 28 Could 2024, Nature Communications.

DOI: 10.1038/s41467-024-48919-5