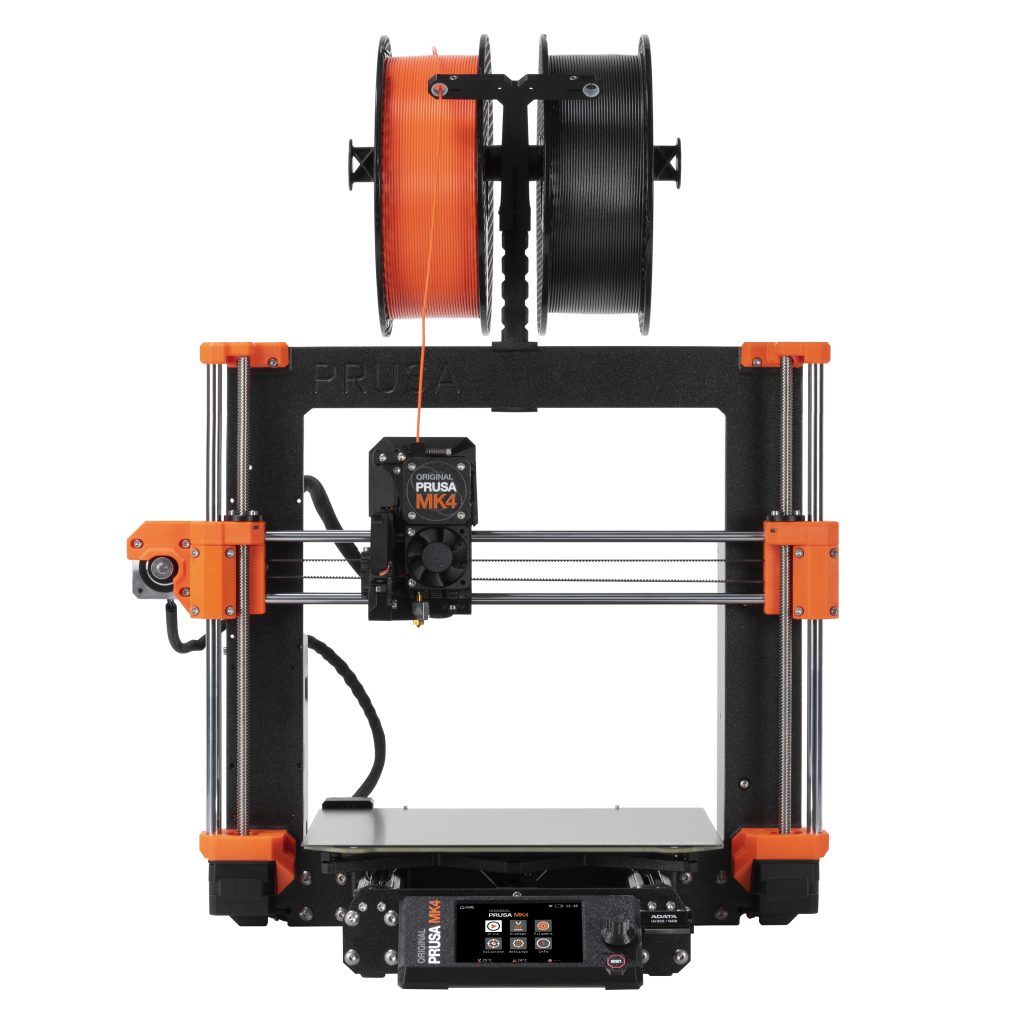

Prusa Research unveils its newest desktop 3D printer, the Original Prusa MK4: technical specifications and pricing

Prusa Research, Czech-based 3D printer manufacturer has unveiled their new desktop 3D printing machine, the Original Prusa MK4. This new machine follows the success of its predecessor, the MK3, which has sold over 350,000 units worldwide over the past five years, and won four consecutive 3D Printing Industry “3D printer of the year” awards between 2019-2022.

Prusa has continued to use the MK3’s proven design but is eager to show off the improvements it made with its new printer. “It might look similar at first glance, however, in fact, we adjusted, improved, or outright replaced 90% of the parts”, commented Prusa Research founder and CEO Josef Prusa.

The printer’s main goal is to improve the user experience. There are many new features that aim to make printing faster, easier and more intuitive. This allows for greater printing possibilities for all levels of printer users. Josef Prusa calls the MK4 “another step towards making the 3D printer technology more accessible for regular users, which are not interested in tweaking and tinkering with the printer – they just want to print.” The MK4 is available to order now, with more information available on the Prusa Research website.

The MK4’s key features:

The MK4 incorporates Prusa’s new xBuddy board, a 32-bit STM32-powered mainboard which replaces the old EINSY RAMBo board used by the MK3. Called the “cornerstone” of the MK4, this new mainboard has been designed, manufactured, and tested in-house at Prusa.

The xBuddy is designed to increase safety and reliability. The board includes dual voltage measurement, heater current measurements, and total input current measurement on its 24V branch. To ensure printer safety, the board disconnects the hotend heater when the current exceeds 2.28A. It also disconnects the heater power supply and heater when the total current exceeds 15. The board includes four thermistors, including heatbreak, ambient and hotend. It also offers power outage recover.

TMC2130 LA drivers are included in xBuddy. There are also many ports available, including an ESP-01 Wi Fi port, ethernet port and service USB-c port. 12C port, accelerometer port (unpopulated), Multi Material Update 3 (MMU3) port and a Nextruder Port.

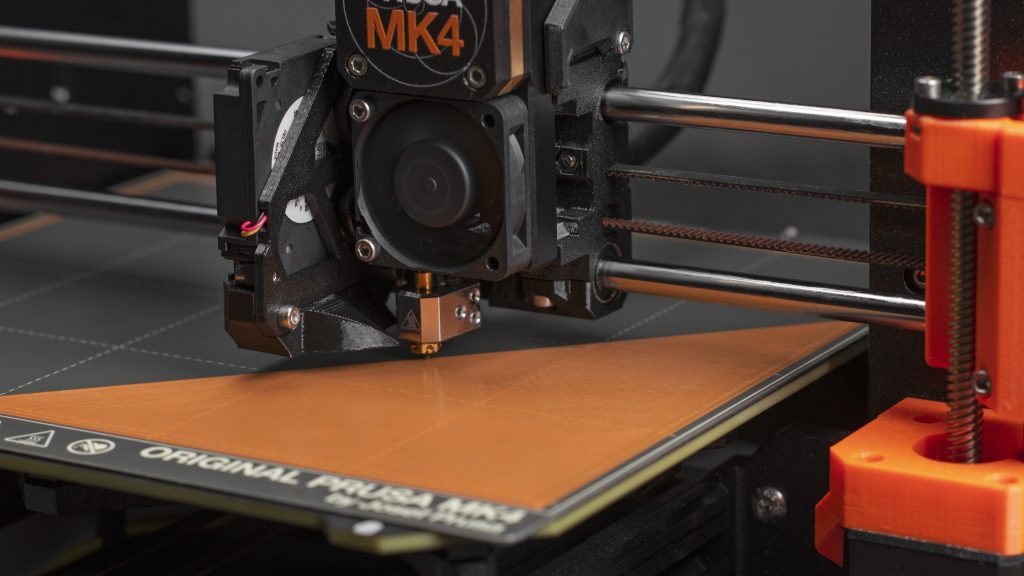

Prusa’s next generation extruder, the Nextruder, is another key addition to the MK4. A smaller, lighter version of the Nextruder already utilized on the Original Prusa XL, MK4’s Nextruder possesses the same Load cell sensor as its larger counterpart. The sensor measures the tension in the extruder to accurately set the distance between the nozzle & the print sheet. This allows the MK4’s automatic printing of a perfect first layer right out of the box.

Additionally, the Nextruder port on a mainboard offers many benefits to the user. Prusa models of the past connected extruders directly to their mainboards, making it complicated and time-consuming for users to replace certain extruders. However, the MK4 incorporates a new connector break-out board, the ‘LoveBoard’, which directly connects all extruder components inside the Nextruder. This feature greatly speeds up the replacement of extruder parts.

The MK4’s new quick-swap nozzle has also been designed to save the user time when making hotend alterations. The Nextruder has thumb screws on either side that can be loosened to remove the entire hotend and replace it quickly and easily. The Load cell sensor automatically calibrates the printer at the beginning of every print after any modifications have been made. Prusa also offers a Nextruder to-V6 adapter that allows any v6 compatible nozzle, including high flow and hardened models, to be used in conjunction with the MK4. A range of nozzles is also available from Prusa (from 0.25 up to 0.8), which can be purchased in their online shop. Additional models will be added in future.

Another key feature of MK4 is its high speed printing. The printer incorporates Input Shaper, and Pressure Advance. These technologies can decrease print times up to 75% while maintaining good print quality. A sample print, which would normally take 80 minutes on a MK3, now takes less than 20 minutes, as shown in the demo video below.

New MK4 models now have a graphic LCD interface. It replaces the older segmented LCD. This color LCD screen is capable of supporting G-code thumbnails as well as longer texts and graphics. An RGB status bar is also added to the LCD screen. It features a programmable RGB set of RGBLEDs in different colors that indicate the state of the printer. A USB-A connector has been placed next to the display. This allows users to store Gcodes on a USB flashdrive.

Prusa announced the MK4’s release, along with the Multi Material Upgrade 3 (MMU3). It is compatible with both MK3S+ as well as MK4 models. This optional upgrade allows the single extruder to print up to five colors simultaneously. The MMU3 offers greater reliability and better controls than previous models. The MMU3 will be available for purchase through the Prusa online shop and shipping is expected to begin in June.

Prices and technical specifications

Original Prusa MK4 prices start at $799 USD per assembly kit and $1099 for the fully-assembled printer. Customers can also buy upgrade packages for existing MK3S+ models. These include MK3.5, MK3.9, and MK4 upgrade options.

| Build volume | 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in |

| Layer height | 0.05-0.30mm |

| Max heatbed/hotend temperature | 300℃ / 120℃ (572℉ / 284℉) |

| Mainboard | STM32 custom 32-bit xBuddy electronics |

| Stepper Drivers | Trinamic 2130 silent stepper drivers |

| Stepper Motors | 400 steps (prevents VFA). |

| Extruder electronics | A custom breakout board to connect fans, thermistors or other parts |

| Filament path | All-metal heatsink, aluminum heatsink, no PTFE tubes |

| Drive system | Planetary Gear System, 1:0 gearbox sensor |

| Nozzle diameter | 0.4mm (default) or other supported nozzle diameters |

| LCD Screen | 3.5” graphic 65k color screen |

| Print surface | Magnetic heatbed with removable PEI spring-steel sheets |

| Calibration of the bed | Automatic, Mesh Bed leveling (only available in the print area). |

| Supported materials | Any thermoplastic, including Nylon or Polycarbonate |

| Wi-Fi connection | Optional ESP WiFi module (delivered with the printer). |

| Advanced | 4 high-precision Semitec thermistors + fan motors RPM Monitoring |

| Print medium | Prusa Connect USB drive / Ethernet / Internet via Prusa Connect |

| Firmware update interface | USB drive |

| Power supply | 240W, made custom by Delta with Power Panic HF |

Subscribe to the 3D Printing Industry Newsletter Keep up-to-date with 3D printing news. You can also follow our blog TwitterLike our Facebook Page, and Subscribe to the 3D Printing Industry YouTube Channel to get more exclusive content

Do you have an interest in working in additive manufacturing? Visit 3D printing jobs View a range of roles available and get started with your career.

The Original Prusa MK4 is shown in action. Photo by Prusa Research.