Team prints edible QR codes using innovative 3D food printer

Like a scene from the flicks, a group of researchers from Singapore College of Know-how and Design (SUTD) has developed new methods to freely produce and customise the meals that we eat.

Their findings have been printed within the journal Future Meals as “Multi-material direct ink writing 3D meals printing utilizing multi-channel nozzle.”

Three-dimensional (3D) printing utilizing meals elements is at the moment the favored method to shaping meals with distinctive buildings, textures, and dietary compositions.

“Printing meals in 3D permits the customization of vitamins, the creation of aesthetically pleasing meals, and the modification of meals texture to swimsuit particular person dietary wants,” explains principal investigator Michinao Hashimoto, an affiliate professor at SUTD wanting into combining using design and know-how in analysis.

Some repurposed meals sources, comparable to okara (soybean dregs), orange peels, and bug protein, are likely to keep off appetites by their appearances and origins. By adjusting the printing parameters, researchers can incorporate edible and nutrient-rich elements from these uncommon sources, and assemble an aesthetically pleasing meal.

For the on a regular basis particular person, this brings to the desk a customized and sustainable means to get the every day grub. On the similar time, people with consuming problems or who’ve issue swallowing (dysphagic) can customise their mealtime expertise and enhance their consuming habits.

Researchers have efficiently printed meals utilizing chocolate, milk, gelatin, and vegetable inks, however these constructs are largely confined to single elements. Current strategies battle with seamless transitions between supplies, resulting in fragmented prints and elevated complexity within the machine printing course of, based on Dr. Lee Cheng Pau, the lead researcher of the present examine.

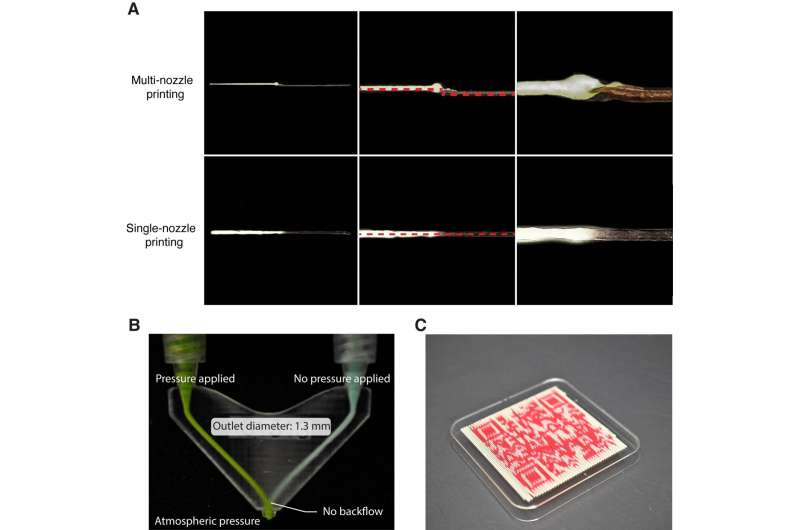

One widespread method makes use of a number of nozzles to carry and eject totally different meals constituents, like having a field of shade pencils to work with. Requiring cautious machine design and nozzle alignment when printing, this method has discontinuous interfaces, the place totally different supplies overlap, and lengthy printing instances.

Affiliate Prof Hashimoto and the group favor a unique method, taking inspiration from microfluidics. With twin inlets and a single outlet, this method mitigates the intricacies of switching between a number of nozzles by combining the meals pipelines earlier than the printing stage.

Combining totally different meals inks by intersecting junctions just isn’t trivial, nonetheless. Backflows into the ingredient inlets are likely to occur with fluids of various rheological properties—comparable to stream and viscosity. For instance, squeezing out a dab of toothpaste requires extra power than pouring out water. If the 2 had been to feed right into a single outlet, pushing out toothpaste would possible ship some paste up into the water inlet.

To beat this problem, the researchers needed to rigorously engineer the design of the meals printer. Step one was to widen the exit outlet of the Y-junction within the printer to accommodate meals ingredient inks which might be high-yield-stress, which require extra pressure to extrude. This transformation gives a decrease resistance for the stream, stopping the ink from going up the incorrect channel within the printer.

As well as, it’s essential to account for the delay within the meals ink transition. As the situation for the switching between inks not occurs on the printing nozzle, the researchers carried out an offset for the printing algorithm.

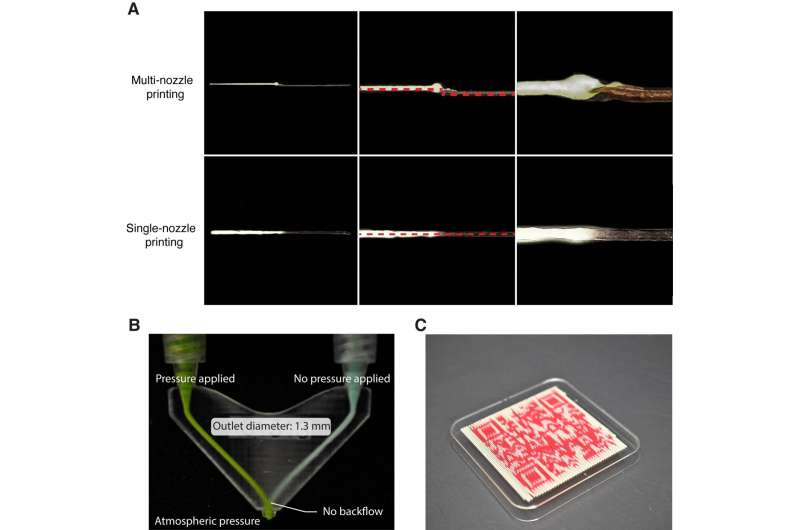

With their intelligent design, the group was in a position to display seamless and steady printing between inks with vastly totally different rheological properties, with minimal backflow. To display the prowess of their system, they printed the SUTD institutional brand and a completely useful QR code utilizing totally different milk inks.

Following up on their innovation, the group hopes to optimize the design and know-how additional to accommodate extra inlets and progress towards industrial scalability.

“Our know-how can be utilized to 3D-print meals consisting of a number of supplies with out compromising the printed buildings and look,” stated Dr. Lee. “It may be utilized in creating meals tailor-made to particular person dietary wants, aesthetically pleasing dishes, and interactive meals experiences comparable to edible QR codes.”

Extra data:

Cheng Pau Lee et al, Multi-material Direct Ink Writing 3D Meals Printing utilizing Multi-channel Nozzle, Future Meals (2024). DOI: 10.1016/j.fufo.2024.100376

Singapore College of Know-how and Design

Quotation:

Workforce prints edible QR codes utilizing modern 3D meals printer (2024, July 3)

retrieved 4 July 2024

from https://techxplore.com/information/2024-07-team-edible-qr-codes-3d.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.